Duilleag umha

Ro-ràdh Toraidh

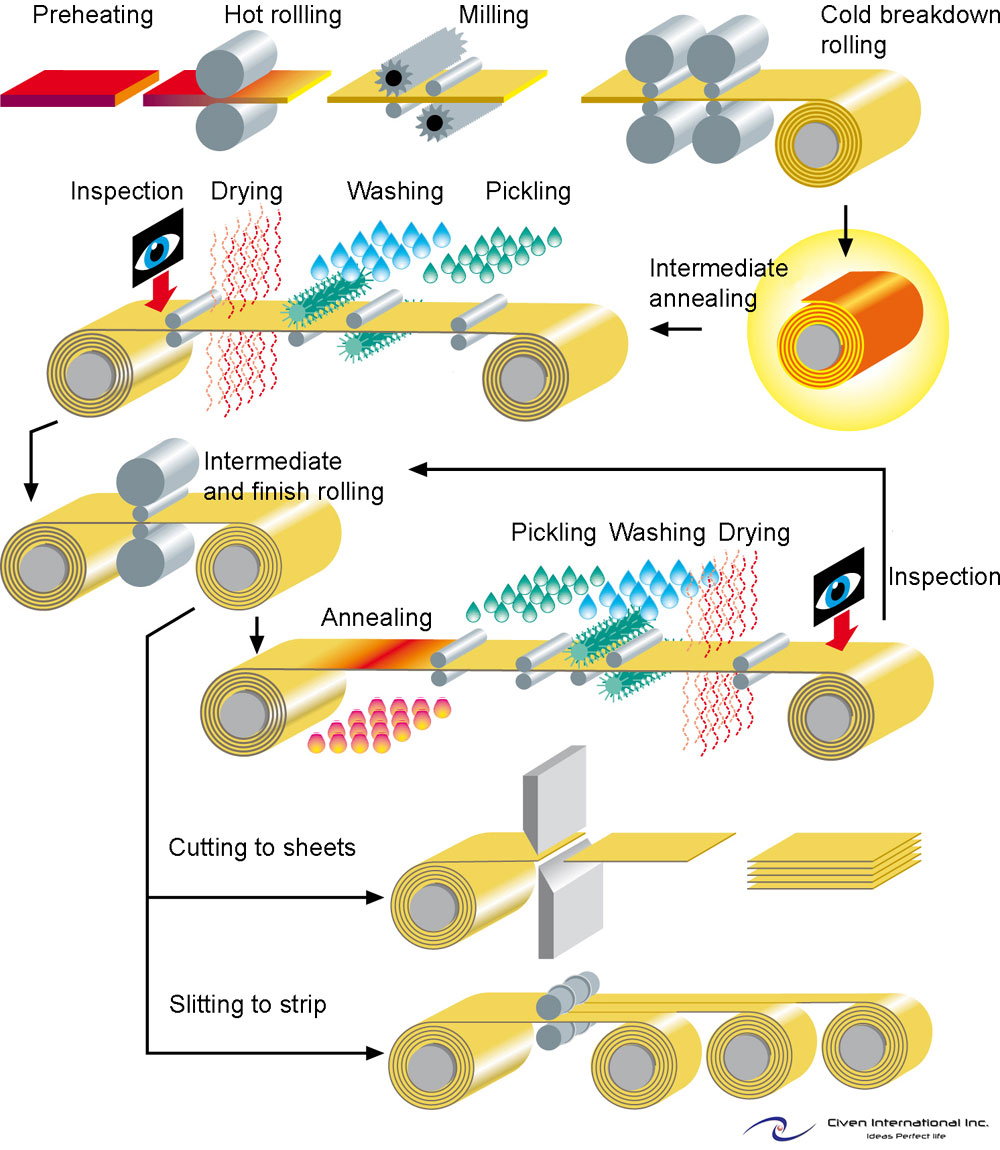

Duilleag umha stèidhichte air copar electrolytic, sinc agus eileamaidean lorg mar an stuth amh aige, tro phròiseasadh le ingot, roiligeadh teth, roiligeadh fuar, làimhseachadh teas, glanadh uachdar, gearradh, crìochnachadh, agus an uairsin pacadh. Coileanadh pròiseas stuthan, plasticity, feartan meacanaigeach, strì an aghaidh creimeadh, coileanadh agus staoin math. Chaidh a chleachdadh gu farsaing ann an gnìomhachasan dealain, chàraichean, conaltraidh, bathar-cruaidh, sgeadachadh agus eile.

Prìomh pharaimearan teicnigeach

2-1 Co-dhèanamh Ceimigeach

| Ainm | Àireamh an aloidh | Co-dhèanamh Ceimigeach (%, Uasmhéid.) | ||||||||

| Cu | Fe | Pb | Al | Mn | Sn | Ni | Zn | Neo-ghlainead | ||

| Pràis | H96 | 95.0-97.0 | 0.10 | 0.03 | --- | --- | --- | 0.5 | Rem | 0.3 |

| H90 | 88.0-91.0 | 0.10 | 0.03 | --- | --- | --- | 0.5 | Rem | 0.3 | |

| H85 | 84.0-86.0 | 0.10 | 0.03 | --- | --- | --- | 0.5 | Rem | 0.3 | |

| H70 | 68.5-71.5 | 0.10 | 0.03 | --- | --- | --- | 0.5 | Rem | 0.3 | |

| H68 | 67.0-70.0 | 0.10 | 0.03 | --- | --- | --- | 0.5 | Rem | 0.3 | |

| H65 | 63.5-68.0 | 0.10 | 0.03 | --- | --- | --- | 0.5 | Rem | 0.3 | |

| H63 | 62.0-65.0 | 0.15 | 0.08 | --- | --- | --- | 0.5 | Rem | 0.5 | |

| H62 | 60.5-63.5 | 0.15 | 0.08 | --- | --- | --- | 0.5 | Rem | 0.5 | |

Clàr Alloy 2-2

| Ainm | Sìona | ISO | ASTM | JIS |

| Pràis | H96 | CuZn5 | C21000 | C2100 |

| H90 | CuZn10 | C22000 | C2200 | |

| H85 | CuZn15 | C23000 | C2300 | |

| H70 | CuZn30 | C26000 | C2600 | |

| H68 | --- | --- | --- | |

| H65 | CuZn35 | C27000 | C2700 | |

| H63 | CuZn37 | C27200 | C2720 | |

| H62 | CuZn40 | C28000 | C2800 |

2-3 Feartan

2-3-1Aonad Sònrachaidh: mm

| Ainm | Àireamh an aloidh (Sìona) | Tinneas | Meud(mm) | ||

| Tiughas | Leud | Fad | |||

| Pràis | H59 H62 H63 H65 H68 H70 | R | 4~8 | 600~1000 | ≤3000 |

| H62 H65 H68 | B B2 | 0.2~0.49 | 600 | 1000~2000 | |

| 0.5~3.0 | 600~1000 | 1000~3000 | |||

Comharra Teòthachd: O. Bog; 1/4H. 1/4 Cruaidh; 1/2H. 1/2 Cruaidh; H. Cruaidh; EH. Ultra-chruaidh; R. Rollaichte teth.

Aonad Fulangas 2-3-2: mm

| Tiughas | Leud | |||||

| Tiughas Ceadaichte Claonadh ± | Leud Ceadaichte Claonadh ± | |||||

| <400 | <600 | <1000 | <400 | <600 | <1000 | |

| 0.5~0.8 | 0.035 | 0.050 | 0.080 | 0.3 | 0.3 | 1.5 |

| 0.8~1.2 | 0.040 | 0.060 | 0.090 | 0.3 | 0.5 | 1.5 |

| 1.2~2.0 | 0.050 | 0.080 | 0.100 | 0.3 | 0.5 | 2.5 |

| 2.0~3.2 | 0.060 | 0.100 | 0.120 | 0.5 | 0.5 | 2.5 |

| Tinneas | Neart teannachaidh N/mm² | Leudachadh ≥% | Cruas HV | |

| M | (O) | ≥290 | 35 | --- |

| Y4 | (1/4 uair) | 325-410 | 30 | 75-125 |

| Y2 | (1/2 uair) | 340-470 | 20 | 85-145 |

| Y | (H) | 390-630 | 10 | 105-175 |

| T | (EH) | ≥490 | 2.5 | ≥145 |

| R | --- | --- | --- | |

Comharra Teòthachd: M. Bog; Y4. 1/4 Cruaidh; Y2. Cruaidh; Y. Cruaidh; T. Anabarrach cruaidh.

Dòigh-obrach Saothrachaidh